The Tamiya TA05IFS is the inboard front suspension version of the conventional TA05 chassis. I originally bought this car because of it's unique design and ability to run very low GT style bodies, unlike many other touring car chassis'. My previous chassis was a Schumacher Mi2EC which I modified extensively to get the front end lower, and this car was just as low from the factory!

Because I like to run scale car bodies I find myself changing car set-up more than most. Normal RC 'racing' bodies are all very similar to each other, do not represent the vehicle they are supposed to model and generally don't excite me. I want to race cars that look like the real thing. These bodies are often heavier than the 'race' shells and more importantly, there's a lot more difference between the shells requiring more extensive set-up changes when the body is changed. On large tracks where aerodynamics play an important role, most of the scale shells will lose out to the aero-designed race bodies. On small slow tracks like the Gloucester club this is not the case. Here, the weight distribution of the shell is the major performance factor. At Gloucester a car without a rear wing lacks rear end grip. The same car with a few grams of weight on the back of the shell handles the SAME as a car with a lexan race wing on and has excellent rear grip. Understanding this fact is what allows the scale body to compete with the race bodies and often win - but it only works on small, slow tracks.

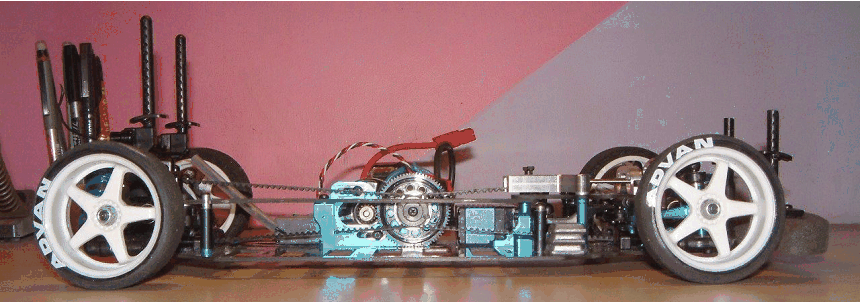

To handle the types of set-up that I needed with my scale shells, I found myself wanting to change spring rates often - especially as the amount of grip available increased over the course of a race evening (debris and dust are brushed off the racing line and tyre additive and rubber coats the fibres of the carpet). The Torsion-IFS suspension conversion keeps the super-low front end profile of the car (in fact lowers it quite a bit more) but allows spring rate changes in finer increments that are also independent of damping rate. This is not possible using conventional coil-over shocks.

The springing is provided by steel torsion bars, that are twisted as the suspension compresses. The point at which the bars are clamped determines their effective length and therefore their stiffness in torsion. The stiffness is highly dependent on the bar thickness so it is important to use equally sized steel rod each side. I used 2mm ground tempered steel. The combined weight of the bars and mounting hardware is actually less than the coil-over system that it replaces.